This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

Welding is a complicated technical science, and there are many kinds of common welding mistakes that everyone from amateurs to veterans fall prey to while welding. Luckily, many of these mistakes can be mitigated by being aware of the metallurgical properties of your materials. Mistakes can also be avoided by correctly preparing your materials and equipment.

So, what are some of the most common welding mistakes? Some common welding mistakes include not prepping materials correctly, not using equipment properly, and using improper materials together in the same welding project. Welding mistakes lead to welding defects such as slag, deformation, burn-through, porosity, brittleness, and undercut.

The most common welding mistakes can be easily avoided through proper maintenance and use of your welding materials and equipment. Read on to find out about common welding mistakes encountered with various types of welding and how to avoid them in your metalwork, as well as injuries that can occur when proper precautions aren’t taken while welding.

What Could Possibly Go Wrong?

Welding does not seem like a complicated science from an outsider’s perspective—you slap two pieces of metal together, apply heat or electricity, and you end up with a weld. But the use of welding torches and the knowledge necessary to properly incorporate different types of metals successfully into a welding project are things that can make the difference between a polished, high-quality result and a bad weld.

Not only can an improper weld lead to unsightly defects that negatively impact the final appearance of the weld, but they can also lead to defects that prevent the welding job from passing any kind of quality assurance inspection regarding manufacturing and assembly.

Even in household projects, improper welding can lead to structural damage in finished metalworking projects and even dangerous situations if the welded object in question is being used under load or as part of a weight-bearing structure.

Whether you are welding in a home workshop or learning to weld like a professional, knowing how procedures can positively or negatively affect your welding quality is the key to constant technical improvement in the craft.

Prepping Your Materials to Avoid Common Welding Mistakes

You can avoid a lot of common problems in your welding by prepping your materials correctly. The most significant issues that come from lack of preparation in your materials (both your base metals and your filler wire) are contaminants such as oil, grease, protective coatings, and other surface debris that can cause irregularities in your weld seam.

Making sure that welding materials are properly prepared and maintained is so crucial to maintaining weld integrity that many industrial welding sites have formal documentation of material preparation through standard operating procedures to make sure that every step of preparation is followed through.

For stainless steel and many other metals, preparing the base metals involves both scoring the surface of the base metals to remove any kind of exterior debris and protective coating, as well as a chemical bath in acetone or a chemical solvent to remove any remaining oxide on the surface of the base metal.

Without these two processes, welding on unprepared base metal can lead to a variety of different welding deformations and problems. Here are the materials needed to prep and maintain your welding materials before a welding operation:

- Clean base metals: Base metals should be cleaned with a chemical solvent such as acetone or LOW VOC PRE. This chemical bath is designed to remove any remaining oxide surface layer after any protective coating has been ground away from steel or other carbon-based alloys.

- Angle grinding: An angle grinder is a useful tool for prepping large, flat expanses of base metal quickly to prep for a welding operation. Angle grinders can be used in conjunction with a flap disc to prepare steel for either TIG or MIG welding operations. Caution should be used when using an angle grinder on thin metal materials, as it can accidentally burn through.

- Sandpaper: For those welders who do not own an angle grinder, eighty-grit sandpaper can also be used to prepare a metal surface for welding. The disadvantage of using sandpaper is that it can be tedious, time-consuming, and has the potential to deeply scratch metal surfaces if not used very carefully.

- Abrasive blasting: Metal that is extremely dilapidated with rust and other debris will need a more substantial level of surface preparation before dosing with a chemical solvent. Abrasive blasting tools can remove rust from even the most battered base metal pieces and is suitable for metal restoration work.

Preparation of the base metal is particularly important in nonferrous metals such as aluminum and titanium, as these metals develop an oxidized surface coating with an extremely high melting point that makes welding difficult. Abrasive blasting preparation should not be used on nonferrous metals, as they are sensitive to atmospheric contaminants introduced by the blasting unit.

It is also essential to make sure that your welding workbench, in general, is free of dust and that your workshop fan is not blowing directly over the workbench area. Massive ventilation can lead to a break in the shielding gas, which can then lead to welding quality issues like porosity.

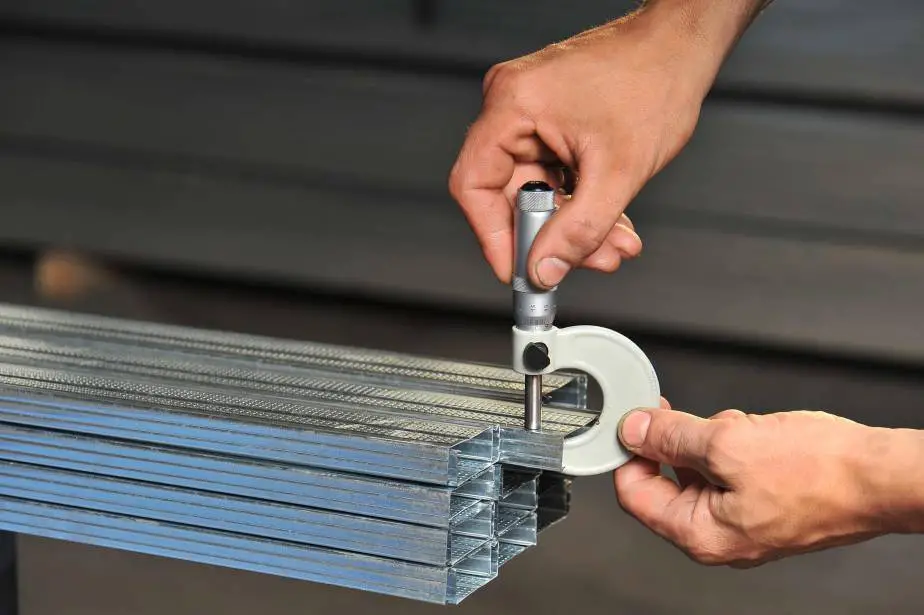

Knowing Your Materials (and Their Thickness) to Avoid Common Welding Mistakes

Another critical aspect of avoiding common welding mistakes other than preparing your materials is understanding how your materials work on a metallurgical basis, and how their thickness will affect the amperage and voltage necessary for a successful weld.

Base metal thickness is one of the essential variables for calculating welding voltage, wire feed speed, and size of electrode. The thicker a base metal is the more the metal will act as a heat sink. The more heat required due to thickness, the higher the current will need to be due to the increased heat needed to complete the weld. Your settings will of course need to be adjusted accordingly. Here’s a great video explaining how to dial in your machine.

Using the Correct Hardware to Avoid Common Welding Mistakes

Other than making sure that you understand the materials you are using and have prepared them before welding, knowing the correct hardware to use for a given situation is crucial. For example, metals such as aluminum should only be welded with a TIG welder, as other types of welding apparatus generate too much heat-affected area, and aluminum is too easily distorted.

Here are some hardware considerations you should think about when it comes to setting up your welding workshop for avoiding common mistakes:

- Electrode/wire selection: Knowing which electrodes and filler wires to use for each specific welding project can go a long way towards helping you avoid mistakes. Filler wire should be chosen not just by metal compatibility with the base metals, but also by diameter, feed speed, etc.

- The machine used: Different kinds of welding machines—TIG welders, MIG welders, and stick welding torches—all have different levels of compatibility with different kinds of welding jobs. It’s your responsibility as a welder to understand what welding machine goes best with particular materials and whether your welding technique is capable of welding the materials at hand.

- Current selection: Incorrect current levels and polarity settings during a welding operation can lead to a wide variety of welding defects including porosity, spatter, poor penetration, and overheating. This, in turn, can lead to a brittle weld. Do not use an electrical welding unit without understanding how the electricity levels affect the welder.

Before you get involved in any kind of serious welding projects, it’s a good idea to study your welding equipment and materials extensively so that you know what your welding unit is capable of taking on (and what it isn’t).

Using the Correct Technique to Avoid Common Welding Mistakes

Knowing the proper techniques for your particular welding type is an excellent way to avoid simple mistakes and develop bad habits that are hard to kick later on in your welding education. Here are the most common forms of welding and the best techniques for each welding type:

TIG Welding

First, if you want to learn more in detail about TIG welding, check out our in-depth article here.

To achieve a good weld in TIG welding, the key is to create a smooth, consistent welding movement down the line of the welding seam. The gap between the electrode and the base metal should also be kept consistently between an eighth of an inch to three-sixteenths of an inch. The TIG welding torch should be held at a fifteen-degree angle to the base metal.

When making a butt weld with a TIG welding torch, the torch should be held at a ninety-degree angle to the base metal. When making a filet weld, the torch should be held closer to a forty-five-degree angle. TIG welding components should always be cleaned spotlessly as TIG welding reacts poorly to both surface and atmospheric contaminants. If you accidentally contaminate the electrode by touching it to the base metal, it should be cleaned and ground down immediately before proceeding.

MIG Welding

Like TIG welding, MIG welding is most successful when the components are cleaned before the welding operation. The key to a successful MIG weld is to keep the amount of wire sticking out of the MIG welding torch short (between a fourth and three-eighths of an inch) and to keep the arc at the very forward edge of the welding pool. This helps prevent slag and uneven beading.

Another essential consideration to think about in MIG welding is grounding. Welding improperly grounded objects will cause the MIG welding unit to waste consumables and increases the chance of unsightly spatter. You could also give yourself a shock if you’re not careful.

A MIG welding gun can be either pushed in the direction of the welding seam or pulled along. A MIG torch that is pushed along the welding pool will produce a weld with shallow penetration, while a torch that is dragged along the weld will have deeper penetration with a narrow, high focus. It is important not to drag a MIG welding torch along a thin metal plate as this can lead to burn-through.

Stick Welding

The main advantage of stick welding is that it can be useful for welding thick base metals, but it is not suitable for metals thinner than 1/8th inch. For an accurate stick weld, you should ensure that the electrode you are using is matched up to the correct voltage setting: AC, DC negative, or DC positive.

Necessary amperage is determined by the electrode type, thickness of your materials, your welding position, and a visual inspection of the weld as it proceeds. The amperage should be adjusted by 5-10 amps until the desired weld pool and seam width and texture are achieved.

On thin base metals, a straight weld can be used to fill the seam—on thicker metals, a back-and-forth movement is necessary. Travel speed should be kept smooth and consistent, with the electrode held in the front third of the weld pool.

It is crucial when stick welding to keep the welding arc small, as lengthening the welding arc to get better visibility of the weld can negatively impact weld quality. Rather than drawing back your hand, shift your head to increase the visibility of the weld seam.

Practicing Welding Techniques for Improvement

No matter which type of welding technique you use, the best way to improve your welding skills is to practice with your equipment regularly. The more often you practice your welding techniques and working with materials, the more experience you develop, and the more confidence you can put behind your welding.

It is also a good idea to continually study welding skills to increase your metallurgical knowledge. The more experience you have with different kinds of welding materials, the less chance you have of making amateur mistakes during your weld.

Common Welding Mistakes and What Causes Them

There are several welding mistakes that new welding students commonly come across in the course of learning how to weld effectively with their chosen equipment. Each of these welding defects is the result of specific environmental parameters that are out of whack, most of which are easily under the welder’s control as long as he or she is aware of them.

Here are some of the most common welding mistakes you are likely to run across and how you can avoid them:

Cracks

Cracks are one of the most severe defects that can be introduced during the welding process since cracks are an unacceptable fault in most quality assurance inspections. More importantly, cracks have the potential to grow larger over time, threatening the overall integrity of the base metal structure.

The main contributors to cracks in a welding job are dirty and ill-fitted base metal pieces or improper welding temperatures. Make sure to adhere to base metal thickness variables to determine necessary heat settings for a successful weld. All base metal pieces should also be cleaned and prepared carefully.

Spatter

Check out our article on what splatter is and how to avoid it here.

In short, spatter is the appearance of molten droplets of metal that fly up from the welding pool during the welding process. Not only does spatter leave unsightly defects on the surface of the base metal that will need to be ground down and reworked to remove, but spatter also increases the chance of a welder becoming accidentally injured through a burn. Spatter also increases the risk of fire in the workshop.

Spatter can result from a variety of oversights, including lack of adequate shielding gas, high current, or incorrect polarity. Spatter can be avoided by ensuring proper flow rates in the shielding gas unit and double-checking the polarity matches the electrode being used. Cleaning the torch nozzle can also help prevent spatter.

Deformation

Deformation is a distortion in the surface of the base metal that can occur as the result of temperature fluctuations during the cooling process. Deformation can be avoided by welding evenly from the inside-out on a welding joint and welding both inside and outside of the joint.

Another way to prevent deformation is to keep welding passes to a minimum. Overheating the base metals through repeated welds can increase the chance of deformation, especially in more delicate metals such as aluminum.

Slag Inclusions

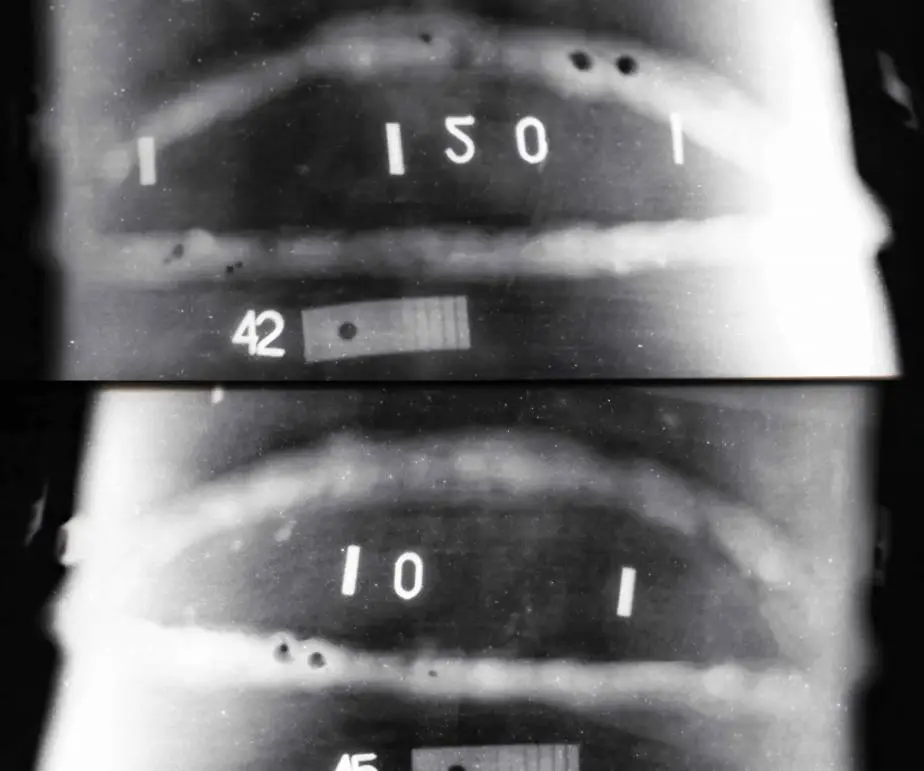

Slag inclusions are the result of flux that gets trapped in the weld pool, preventing full fusion of the welding seam. Slag shows up as lines along the line of the weld that is most readily identified through radiographical inspection.

Lack of penetration leads to weakness in the resulting weld. It can also lead to heat affecting the surrounding area if the welding time is extended to mitigate the lack of penetration.

Along with making sure that the electrical settings on the welding unit are correct, slag inclusions can be avoided by using well-maintained, flux-coated consumables in the welding unit. Because slag inclusions are smooth defects and do not show up as sharpened surface edges, they are sometimes permitted by some quality assurance codes.

Porosity

Porosity is a problem resulting from two primary causes: contaminants on the surface of the base metal, and the absorption of atmospheric gases into the welding pool, mainly hydrogen. Once the welding pool cools, these bubbles of atmospheric gas leave hollow bubbles within the weld, leading to weakness in the resulting joint.

The main ways to prevent porosity in a weld are to use correct gas shielding techniques (managing proper flow rate and avoiding heavy ventilation in the welding area) as well as adequately preparing all base metals and consumables before welding. Just taking steps to ensure that welding materials are clean and well-shielded can prevent up to 90% of porosity defects.

Unlike cracks, porosity has acceptable levels depending on the type of welding being performed, so it is not often considered a disqualifying defect in a weld when it comes to technical assurance.

Brittleness

Brittleness in a weld is the result of improper cooling techniques during the post-processing of a welded assembly. If a welded assembly is quenched (or cooled down) too quickly, the resulting contraction of the base metals can introduce brittleness to the weld joint.

Another contributor to a brittle weld is a greasy or oily welding surface. This can be easily avoided by making sure to wipe down all base metals with acetone or some other chemical solvent to remove any residual chemicals before beginning to weld.

Incomplete Penetration

Incomplete penetration occurs when the filler does not entirely penetrate the joint to fuse fully. Incomplete penetration is the result of poor adhesion between the filler bead and the base metal.

Incomplete penetration is considered a severe welding defect because the spaces left in an incomplete weld can allow for the collection of corrosion that will inevitably compromise the integrity of the joint. If this weld is needed for structural integrity, it is a matter of time before the structure becomes compromised.

To prevent incomplete penetration, verify that the correct welding angle, settings, and arc lengths are adhered to. Care should also be taken to choose a filler or electrode that is fully compatible with the base metal.

Incorrect Wire Delivery

If filler wire is not feeding correctly through the welding unit, this is usually the result of a lack of maintenance on the welding torch itself. Faulty wire delivery can be the result of an overly large nozzle tip, an improperly sized gun liner, a worn-out welding gun, or a worn-out drive roll.

Bad Connections

Bad connections in your welding unit can lead to an unstable welding arc, which in turn can lead to many different quality issues with the resulting weld. Before beginning any welding operation, be sure to do a quick visual inspection of all welding equipment and make sure that none of it needs to be cleaned, repaired, or replaced before welding.

Your welding gun tip especially needs to be inspected and cleaned as it is often overlooked. Check out our article on why a welding torch pops and how to fix it here.

Improper Shielding Gas Flow

An improper shielding gas flow can lead to a break in the protecting cone of shielding gas surrounding the weld pool, which in turn can lead to the introduction of contaminants such as atmospheric moisture and elements like hydrogen and nitrogen.

Improper shielding leads to severe welding defects and can be avoided by learning how to operate your shielding gas tank set up correctly and making sure that flow rates are adequate to maintain a protective gas cone over the welding area.

Another way to make sure that shielding gas works as intended during a welding project is to make sure that any ventilation in the welding workshop is directed away from the welding workbench. While keeping the welding workshop ventilated is essential, a draft is capable of pushing the protective bubble of shielding gas away from your welding pool, leaving it vulnerable to contamination.

Bodily Injuries That Can Occur from Welding

Ruining your weld and having to rework it is the least of your concerns when dealing with a welding unit. While this form of technology is one of the most powerful fabrication technologies in the world, it is also one of the most dangerous. We have an in-depth article on common welding injuries that I recommend you read here.

Here are some of the bodily injuries that can result from welding:

- Arc flash: Similar to a severe sunburn for your eyes, arc flash is the result of welding without protective gear over your eyes. Even brief exposure to the bright UV radiation resulting from a welding arc can severely damage a person’s eyes, and repeated exposure can even lead to permanent blindness. For this reason, welding helmets, visors, and goggles are crucial protective equipment in welding.

- Burns: The temperatures involved in welding are several hundreds of degrees higher than those temperatures necessary to melt human skin, which means that great care should be taken to avoid contact with slag, spatter, and other molten metals in the welding workshop. Welding aprons, gloves, helmets, and long-sleeved shirts can help prevent painful and disfiguring burns.

- Skin cancer: Other than eye protection, another reason that welding helmets are essential is that they protect the face from UV exposure, not just the eyes. Over a welder’s career, repeated exposure to UV radiation in the face can lead to skin cancers, especially if no other form of UV protection such as sunblock is used.

- Electrocution: Welding units are high-voltage machines, and the operating panels should never be removed, and repairs should never be made while the welding unit is connected to a power source. It is possible to be shocked by faulty welding equipment, especially in wet conditions, which means it is vital to inspect your equipment before use every time carefully.

The forces used in welding can be dangerous to the human body, but luckily most welding injuries can be avoided with just a little common sense and preparation.

Common Welding Mistakes Are Avoidable

While it is common for new welders to make a wide array of mistakes while they are learning to weld effectively, the good news is that many of these mistakes can eventually be avoided entirely through the application of both welding knowledge and lots of practice.

If you make a point to become familiar with your welding equipment, your consumables, your base metals, and your joint types, you’ll be well on your way to preventing most of the welding mistakes you’d eventually come across in the shop.

Sources:

https://garage.eastwood.com/eastwood-chatter/how-to-prep-metal-for-welding-quick-tip/

https://www.welderdestiny.com/base-metal-thickness.html

https://www.weldersuniverse.com/welding_machines.html

https://www.millerwelds.com/resources/article-library/welding-tips-the-secret-to-success-when-tig-welding

https://www.agriculture.com/machinery/tools/welding/11-tips-to-sharpen-your-mig-welding_245-ar52169

https://www.twi-global.com/technical-knowledge/job-knowledge/defects-imperfections-in-welds-slag-inclusions-043

https://www.thefabricator.com/thefabricator/article/arcwelding/22-possible-causes-of-weld-metal-porosity

https://www.lincolnelectric.com/en-us/support/process-and-theory/Pages/mig-problems-remedies-detail.aspx