This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

Even if you are new to welding, you have probably heard the term ‘solder’ at one point or another. It is mostly used in the electronics industry, although it can also be used for connecting pieces and components together to secure them in place. However, some people may find themselves asking the common question of whether or not they can use solder for welding.

Can you use solder for welding? Solder is mainly used in soldering, but it can be used for welding as well. Keep in mind, though, that solder is not as strong as other types of materials that can be used for welding. The solder should be used for minimal, less strenuous projects such as electronics or holding two small pieces together.

When it comes to solder, it can be challenging to know when and where to use it. If you don’t know what solder actually is, the problem becomes even more troublesome.

In this article, you will see a breakdown of all the facts associated with solder. You will learn what solder is and what types are available as well as how it is commonly used.

What is Solder?

For the most part, solder has always been used in the electronics industry. The original solder was made from a unique blend of tin and lead.

However, in more recent years, there has been an influx of different materials being used to make solder. At the end of the day, though, different types of solder are used in different ways and have their own purpose.

Solder can be used in a wide number of ways.

While you will most likely find it in electronics, you can also use it in plumbing and small areas of welding. However, solder is often referred to as a 60/40, meaning it has a combination of 60% tin and 40% lead.

This blend creates a ‘Eutectic Mixture’.

What is a Eutectic Mixture?

You might think that this chemical term has nothing to do with solder and welding, but it’s the root of the answer when it comes to the question of whether or not you can use solder for welding.

Eutectic Mixture essentially describes the melting temperature of a solid. In this case, you are considering the eutectic mixture of solder.

When it comes to the 60/40 combination of many solders used in welding, they have a very low melting temperature. While this means that they are easily welded, it also means that they aren’t necessarily strong.

Since solder lacks overall strength, it is not commonly used in big projects, like welding a bed frame together or installing the railing for a building.

If you decide to use solder, you may risk the metals snapping off. This is why solder is used in smaller projects that won’t require a heavy load, like electronic pieces or plumbing items.

What About Flux?

If you have heard anything about solder you may have heard the term ‘flux’ as well. Flux just so happens to be another reason why solder isn’t high on the list when it comes to welding.

But what exactly is flux and what does it have to do with solder?

Well, in order for the solder to bond correctly to other solids, flux must be present.

Flux is a certain type of acidic mixture that is capable of removing oxides from a joint, thus allowing the solder to flow into the joint. While the solder flows onto the joint, a good, strong bond is made between the two solids.

So, flux is a good thing, right? While flux is a necessary element of solder and welding, it can also act as an irritant.

When the solder is being heated up and flux is released, the brown liquid gives off a highly pungent and irritating smoke that can cause problems to the welder.

This is why you should only use solder while welding in a well-ventilated area.

Sizes of Solders in Welding

Solder can be used in a variety of different ways when it comes to welding. Because it is a weaker material, it is generally used with electronics.

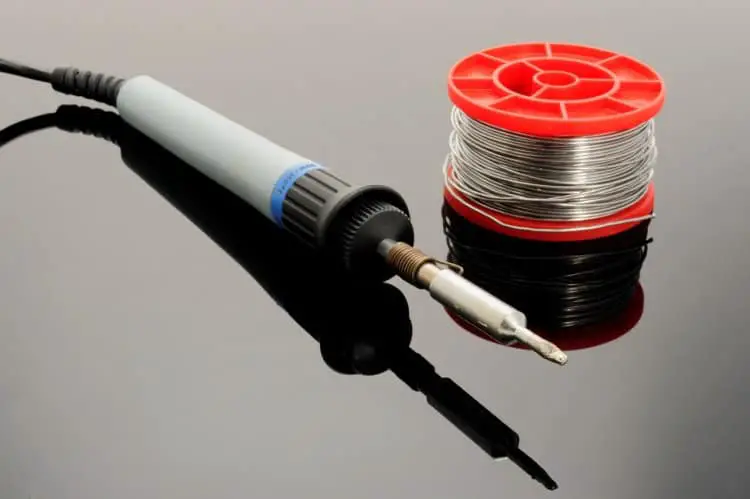

However, that’s not the only way you can use solder. A solder that is used in welding for electronics is usually a thin wire.

This makes it a lot easier to handle and melt into areas where two joints need to be welded together.

When it comes to electronic solder, you will almost always want to use a smaller, thinner line of solder.

Larger projects that are working with more ‘normal’ sized joints may require a solder that is wider. Trying to use thin, electronic solder on a normal joint will be challenging to work with because the joints are longer and larger.

When choosing a solder for welding, you have two types of solder wire that you can choose from: Standard Wire Gauge, or SWG, or America Wire Gauge, also known as AWG.

For the most part, a regular circuit for welding solder will need around 20 to 22 SWG, which is 12 to 21 in AWG.

If you are dealing with larger, thicker joints, then you should consider an 18 SWG, which is a 16 AWG.

Is all Solder Made from Lead?

Exposure to lead can cause a multitude of health problems, which leaves some welders wondering if there is another option than the typical 60/40 solder commonly used in all types of welding.

The good news is yes, there are lead-free solder types available to the public. In fact, some places, like Europe, are banning any type of solder containing lead.

So, what new types of solder are currently being offered to the public?

The most popular option is the solder that is made from a mixture of 99.3% tin, with the rest being copper.

The reason why this particular solder replacement is so popular is that it has a similar melting point as the 60/40 lead solder, so no big changes need to be made while welding.

The other popular choice for lead-free solder is a blend of tin and silver.

However, it is a bit more expensive than the tin and copper blend, so it might not be used widely. It also is known for having a lower melting point, which can cause some trouble while welding.

This type of silver solder is sold under the name ‘Lead-Free Silver Solder.’

Don’t confuse it with other silver solders available for purchase because those are typically sold as a reel of silver solder.

If you are planning to choose lead-free solder, then you should know the following:

- Lead-free solders with copper have a slightly higher melting point, while lead-free solder with silver is lower. For the most part, it should not be too noticeable. However, there may have to be some changes while you’re welding with your soldering iron.

- Lead-free solders are used for the same purpose as regular solders. This means that they are typically formed for electronic use, although some small-scale projects will find a use for them. This also means that lead-free solders shouldn’t be used for anything that will experience strenuous activity or high weight. They will break.

Conclusion

Solder can be used in welding, although it is fairly weak.

That being said, solder does serve its purposes in small-scale areas, especially for electronics. Keep in mind that there are different sizes and types of solder and that some kinds contain lead while other kinds are lead-free.

As long as your project is small, solder is suitable for use.