This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

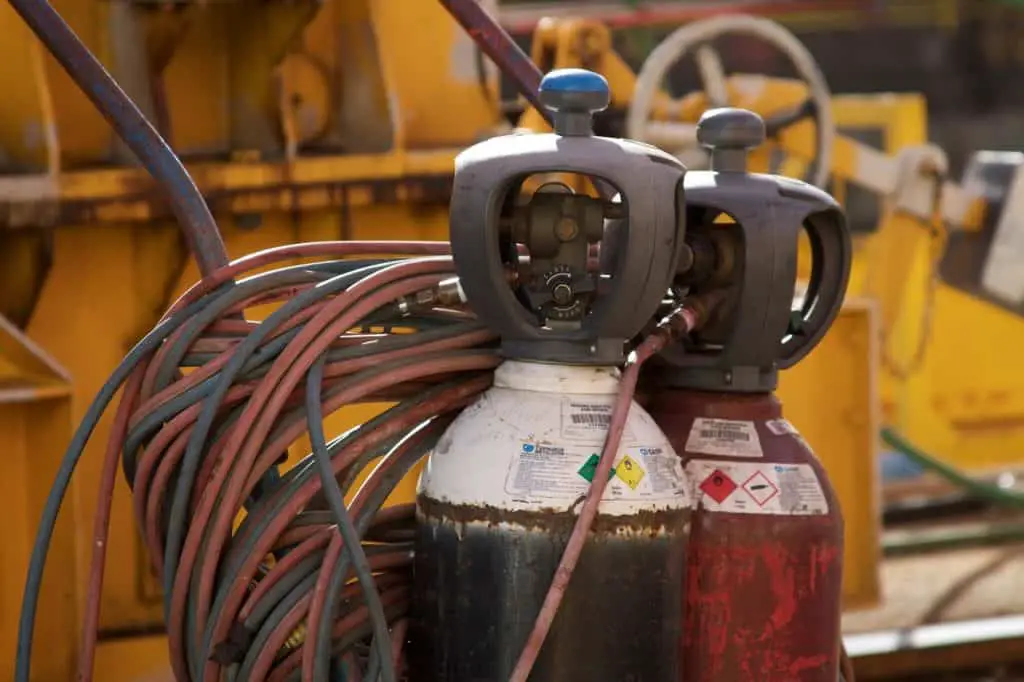

Welding tanks play a crucial role in the welding process. They hold and pressurize the compressed gas used to run your entire operation. Gas tanks are everywhere in the industrial world, and some of them look extremely old and worn out. It’s hard to imagine they are very good at their job anymore.

Do welding tanks expire? Yes, welding tanks can expire. There isn’t an expiration date on them, but they can certainly lose the ability to hold the pressure necessary for their work. Regular inspections are required for all compressed gas tanks to ensure they are still in working order and don’t need to be taken out of commission.

Sometimes it’s easy to tell when a welding tank is past its prime because of some noticeable damage to it. Getting your tanks tested is crucial to make sure you aren’t using a potentially faulty tank. Continue reading below to learn more about how long welding tanks can last and how they are tested for use.

Do Welding Tanks Expire?

Welding tanks can expire in a way, but not from a set time or date. When a gas tank can no longer perform the necessary function for which it was made, then it is considered expired, and it’s time to retire it. A tank having a lack of proper pressure or a leak in your tank can result in some pretty adverse outcomes.

Though your welding tanks can expire, they don’t go quickly. There is no set shelf life of a gas tank. They can and should last several years. The way you determine if a tank is past its prime is to have it inspected. A hydrostatic test will be performed to ensure your tank is still good to go.

There should be a manufacture date as well as inspection dates stamped directly into the metal of the welding tank. These dates are laid out with a month and a year. For instance, 8-19 would refer to August 2019. Inspections are required for the safety of everyone around the gas tanks and must be performed every 3, 5, or 10 years.

Does Welding Gas Expire?

The gas inside of your welding tank is another story entirely. Gas on its own won’t ever expire. There is no shelf life for your welding gas. You could leave it untouched for a decade and go right back to using it without any trouble at all.

The trick to keeping your gas ready to use is to keep it pressurized. If for some reason your tank loses pressure, your gas will no longer be usable. As long as it is appropriately stored, pressurized gas is practically everlasting.

One small problem with leaving gas to sit is the chance of separation. If you are using a mix of two gases like carbon dioxide and argon, storing the tank standing up can lead to them separating in the tank. To remedy this problem, lay tanks on their side and roll them around to encourage the gases to mix once more.

Getting Welding Tanks Inspected

It is required by law that gas tanks be inspected every 3, 5, or 10 years to ensure they are still in working order. The time between inspections will depend on a variety of factors and should be discussed at every inspection, so you know when to come back.

The testing most commonly used for gas tanks is called hydrostatic testing or hydro testing. It is a way to formally test the structural integrity of a container made to hold compressed gas.

A hydrostatic test is performed by filling the tank with water. The tank is then pressurized above what it usually would be for day-to-day operations, usually 150%. The test measures and records the expansion of the tank to ensure it doesn’t surpass a specific limit which would render it unsafe and therefore unusable.

Water is used for this test because it is virtually incompressible. Because of this, the water helps reveal leaks or changes in the tank’s shape as pressure is applied.

Once a tank is tested, it will be stamped with the newest inspection date as a reminder of when it must be inspected again. 5-year inspections are the most common, followed by 3-year inspections. Sometimes you won’t be required to get another check for ten years but only under particular circumstances.

If a tank is getting older or losing some of its structural integrity, it will be rated to hold less pressure than before. The psi level of the container might also be stamped next to the inspection date and shouldn’t be exceeded for your safety.

Safety Tips for Compressed Gas Tanks

It is crucial always to be safe while you are welding and take certain precautions to avoid injury. The same can be said about the gas tanks used for the welding process. Compressed gas tanks pose certain risks that can be avoided if you put these tips into practice.

Tips for Compressed Gas Tank Safety:

Store gas tanks correctly

Regularly check gas tanks for damage

Always secure gas tanks

Be careful when opening gas tanks

Handle empty gas tanks properly

Storage: The specifics of how you should store your compressed gas tanks depends on where you are and what kind of gas is in them. However, there are a few hard and fast rules you should always follow:

Keep gas tanks out of temperatures exceeding 125°

Keep out of direct sunlight and away from sparks or flames.

Separate different kinds of gases, such as oxidizers and flammables into separate storage compartments or areas.

Always store acetylene tanks vertically, never on their side.

Inspection: Always take the time to look over the gas tanks for any damage like dents or punctures before using them. Any container you use should have a clear description of its contents. Also, check the valves and regulators to ensure they haven’t been compromised.

Security: Keep your gas tanks from falling over and rolling away by securing them properly before you begin working. Use ropes, chains, or other means of tying them down so that they don’t cause any damage by tipping over. If there is nowhere to secure them, you can secure gas tanks to each other to reduce the risk of falling.

Opening: Ensure there is no damage to any valves before you open them. Do so slowly to prevent the gas from escaping too quickly and damaging the valve seat. If a valve is stuck, don’t force it or use lubrication to try to get it open. It’s best to consult a professional to help you.

Empty Tanks: Don’t empty a gas tank, it’s best to leave some residual pressure inside. Make sure the tank’s valve is securely closed and mark the container as empty before storing it. Store empty shells separately from filled tanks.

Your Welding Tanks May Last Longer Than You Do

Compressed gas tanks are an incredibly useful tool in welding. They perform a crucial job and are under a lot of pressure, no pun intended. It’s natural to wonder if all that work could wear them out at some point.

It’s possible for welding tanks to no longer be of use to you. They could take on too much damage to be able to function correctly. They could no longer have the structural integrity necessary for holding the needed pressure. It’s not uncommon, however, to see tanks from the early 1900s still being used in welding today.

If you are worried about a gas tank, it’s best to put it to the side until it can be inspected. If there is noticeable damage, then you certainly shouldn’t be using it. Don’t take any chances with compressed gas tanks. Playing it safe is much better than the alternative. For more information on welding tanks, check out our article on common welding cylinder sizes here.