This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

If you have ever been given the task of welding for a big project, you have likely been presented with a welding blueprint. Reading a welding blueprint is a challenging task that not all welders have experience with, but reading one is necessary to ensure quality work is completed in a timely, compliant, safe manner.

How do you read a welding blueprint? The typical welding blueprint will have the view of the project from the top, front, and right side views. From these views, you will see a variety of welding symbols telling you what welds you need to do and where they need to be done to complete the project with accuracy.

When a welder looks at a blueprint, it shows precisely what the expectations of the given project are. To ensure expectations are met, a welder needs to know the various parts of a welding blueprint. In this article, you will learn the parts of a welding blueprint, the symbols used, and what they mean. Read on to find out more!

What Are the Parts of a Welding Blueprint?

Before you can begin to interpret the myriad of letters and symbols on a welding blueprint, it is essential to know the components or parts of a welding blueprint. While it may appear to be a jumble of lines, arrows, and letters, each part is significant.

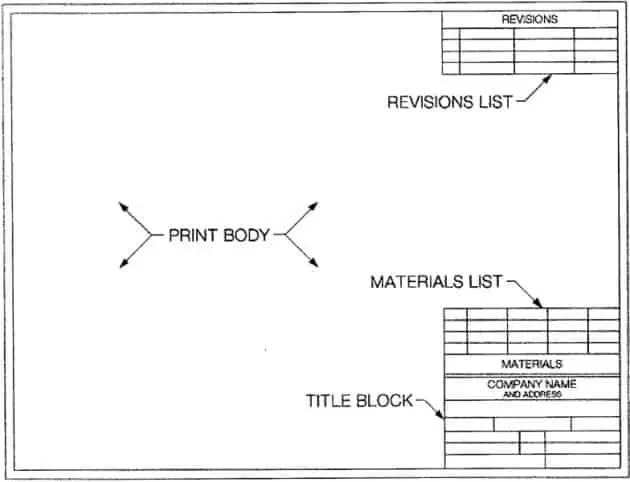

According to the article Welding Symbols, there are typically six parts in a welding blueprint:

- The revision blocks

- The drawing numbers

- The reference numbers and dash numbers

- The bill of material

- The scale

- The title blocks

The layout is a lot like shop plans you have probably seen before. Here is an example:

Each component of the blueprint is vital to the job that is being completed, so the welder must know how to read it.

Revision block: When blueprints are drafted, there are often changes that need to occur during the building process or beforehand. When changes are made to a blueprint, it needs to be documented. The revision block is where this documentation will occur. It may be as simple as a date stating when the revision was made, or it can contain a number to reference the area in which changes were made. This block is typical in most blueprints but may not always be present.

Drawing Number: Just like a book, many blueprints, especially those for large scale jobs, will have multiple pages to reference. To make sure all parts of the plan are accounted for and used correctly, there are numbers assigned to each drawing.

Reference numbers and dash numbers: These numbers are used to help keep the process used organized. Sometimes a process may be required on multiple parts of the drawing; to ensure continuity, a reference and dash number will be used. If the process is only used on one portion of the job, you will likely only find a reference number.

Bill of Material: This is a part of the blueprint where all the materials needed to complete the job will be listed. This is an extremely detailed part of the blueprint with sizes and quantities for each item.

The Scale: The welder will look at this portion of the blueprint to determine the exact size of the actual project instead of measuring the blueprint, which may have been printed on a smaller scale to fit on the sheet. This ensures the item being built is appropriately sized.

Title Block: The name of this part is self-explanatory, as it is the identifying portion of the blueprint. It may have the name of the project or the number related to the project blueprints. If you are working on a project with multiple parts and blueprints, this will help the welder keep track of which project needs a specific blueprint. It is much like the title of a book.

As you can see, welding blueprints are quite organized and extremely detailed. Even if all the parts of the blueprint make sense to you, it may be a struggle to decipher the meaning behind all the arrows, lines, and letters that make up the actual blueprint.

What do The Letters on Welding Symbols Mean?

Welding blueprints can be extremely overwhelming when viewed by the untrained eye. Many different letters and codes are used by welders that can only be defined by welders experienced in deciphering blueprint codes & symbols. Because of this, welders that focus on large scale engineering projects need to be trained to read a welding blueprint.

There are eleven letters that are most seen on blueprints that help guide the welder during the build.

| A | Angle of countersink |

| C | Chipping finish |

| F | Finish symbol |

| G | Grinding finish |

| L | Length of weld |

| M | Machining finish |

| N | Number of spot welds or projection welds |

| P | Pitch of Welds (center-to-center spacing) |

| R | Root opening; depth of filling |

| S | Depth of Preparation; the size of strength |

| T | Specification Process |

These are all welds that are familiar to any welder that has taken the coursework to become a certified welder as they are commonly used in many projects, both large and small.

When looking at these letters, you will notice they each have very distinct purposes for the welder, so they must be followed accurately. Along with the letters on the diagram, these will be combined with weld symbols. When looking at blueprints, you will see two different symbols: weld symbols and welding symbols. Each of these symbols is distinctly different, although they sound similar.

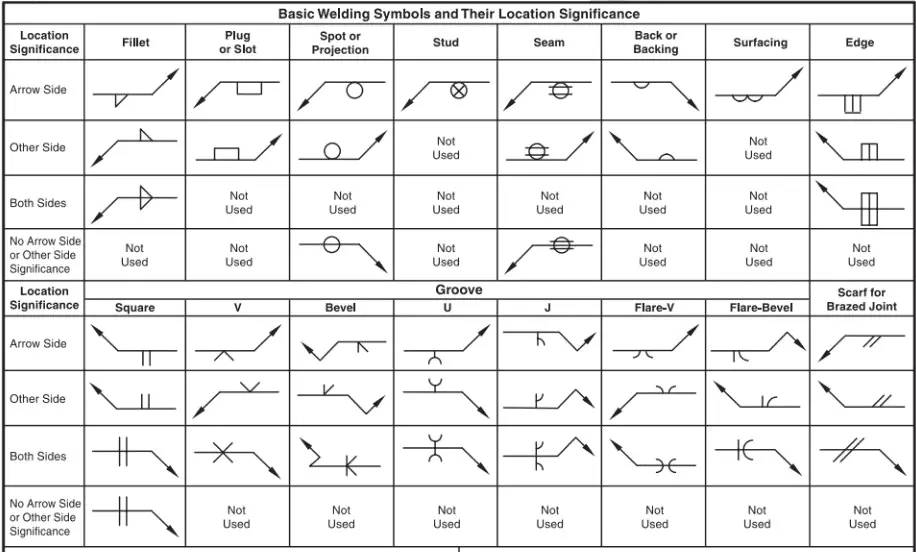

Weld Symbols: Weld symbols are symbols that tell the welder the type of weld they need to perform.

Welding Symbols: Explain the method of welding that needs to be used to complete the welding task.

What are the Most Common Welding Symbols?

When looking at welding symbols, there are many different ones the welder must be familiar with. According to the Universal Technical Institutes article, Welding Blueprint Symbols: What are They and How do You Read Them? the most common symbols are:

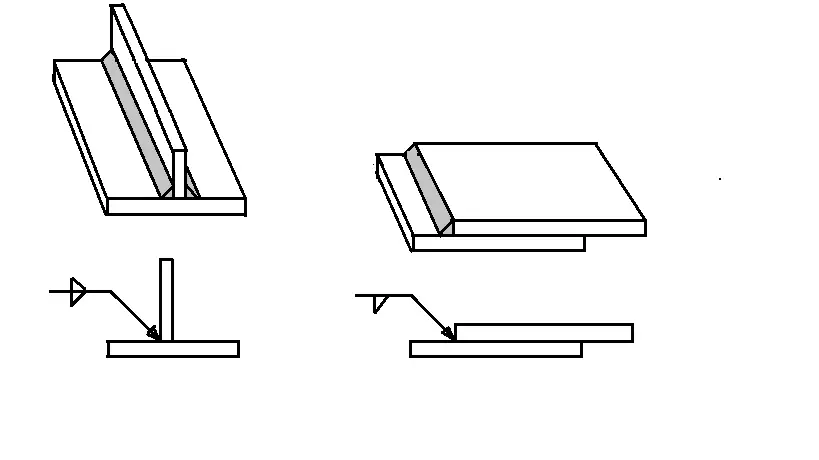

- Fillet Welds: Fillet welds are used to make corner, lap, and T-joints.

- Groove Welds: There are many different types of groove welds that you need to be familiar with when reading a blueprint. They are typically found when you are connecting two edges, also referred to as edge to edge joints.

- Plug and Slot Welds: This type of weld is a bit more complicated, as it requires the drilling and filling of holes when putting materials together that may overlap.

- Spot or Projection Welds: Spot welding is an extremely common type of welding that involves minimal welds to be used. This technique is used when two items are joined with a small dot of welding material.

- Seam Welds: When seam welding, you are virtually creating a seam between two pieces of metal that are being fused.

- Back Welds: As defined by the American Welding Society (AWS), a back weld is used at the back of a single groove weld.

- Melt Through Welds: When this process is used, the weld is only on one side of the metal, but you can see where it melts through on the other side.

- Surfacing Welds: You will typically find these welds used when an area needs to be built up. It is not often used to connect pieces of metal, but to prepare them to be connected.

- Flag Toward Tail Field Weld: This symbol is used to offer direction when a welding job has two locations to be completed. Often a welding job may need to be started in a garage or studio before being moved to the destination. When this situation arises, this type of weld is used and helps indicate where the welding needs to pick up once it reaches its’ destination.

- Flange Weld: According to Science Direct in the article Joints for Process Piping Systems, the flange weld is most commonly used with pipes. The flange is the flat portion on the end of the pipe that is either fitted to another pipe or a flat surface.

- Contour Welds: Contour welds are an advanced form of welding that is commonly used for engineering or construction jobs and is one of the final weld processes as it will be the weld that can be seen on the surface. According to the book Interpretation of Metal Fab Drawings, three specific contour welds are used: flush, convex, and concave.

- Flush: the flush or flat symbol is designated by a straight line.

- Convex: this method is demonstrated by using a smiley face symbol

- Concave: this method is demonstrated by using a frown symbol

- Note: They are not referred to as a smiley and frown face, but it is an easy way to visualize what each symbol looks like if you are not familiar with the terms convex and concave.

When these specific symbols are combined with the welding letters, it provides the welder with a roadmap of sorts to complete a job successfully. To the untrained individual, these lists have many confusing terms that just do not make sense, but to the trained welder, these letters and symbols allow them to begin making sense of the project in front of them.

Can All Welders Read Blueprints?

It would be great to shout a definite yes to this answer, but that is not the case. Not all welders can read welding blueprints. Many welders never take formal training before beginning their work in the trade. Some individuals turn a hobby of welding into a job without schooling or certification. While there is not anything wrong with this route, it often results in welders that may not be familiar with the terms used or symbols.

When a welder completes their training courses, there is no requirement to take a class with blueprint reading. Most welders do not plan to work on projects that would necessitate the reading of a blueprint, so it does not make sense for them to pay for and take a course in blueprint reading. However, if there is a welder that plans to work in the field of engineering with their welding certification, it is a necessity to take courses to learn to read blueprints.

If a welder chooses not to take a course in blueprint reading during their basic welding training, the company they work for will likely pay for the course if it is required for their position. This would be especially true if a welder is moving through the ranks in their position.

Why is it Important to Know How to Read Blueprints?

If a specific course is not required to learn to read welding blueprints, you may be wondering why it is even important. Think about this: if you have a welder working on a large office building or even a residential building that doesn’t know what basic welding symbols mean, would you feel safe walking into a building they have helped to construct?

Do you want a subpar welder working to build the body of a car? These are two examples of times a welder needs to know how to read a blueprint accurately. Other reasons a welder should know how to read a blueprint are:

Quality of work: If an individual knows the exact expectation for the specific job they are doing, the focus of the job can move to quality instead of quantity. When an individual has a guide to go by, no matter what job they may have, the quality of their work is likely to improve.

Shorter work period: Just like any job, when you have a detailed plan of action with specific steps to follow, not only does the quality of the work improve, but it also shortens the time you need to take to do the work. The time is often shortened because you do not have to create a plan of action, and the steps and materials are all written out for you.

Saves money: When an individual can accurately read plans, the time is shortened, the quality is improved, and money is saved both from payment of time and the use of materials.

Fewer errors: When the job is clearly defined by the blueprint, it eliminates the chance for errors to occur. Remember, errors are a part of human nature, but they can be significantly reduced when a welder can read and follow a blueprint accurately. This limit in errors is also a way to save money on projects.

There are many advantages to being able to read a welding blueprint with accuracy. While many companies do not require this skill, some are dependent on a welder’s ability to read a blueprint with high accuracy.

Do All Welders Know What Welding Symbols Mean?

Just like all welders are not able to read blueprints, not all welders likely know what every welding symbol means. A welder’s knowledge of the symbols is going to be based on their primary area of work. If they are doing simple welding jobs, they may not know some of the more complex welding symbols.

When a welder is going to trade school, they will be familiarized with many of the weld symbols, but they may not retain the information, or they may forget it because they don’t frequently use the welds in their business.

One problem that occurs among those being trained as welders (and many other professions for that matter) is a lack of attention to the books and reading material, which is where these items would be highlighted and explained.

Many individuals go through their entire schooling for welding without really taking time to focus on books or written material because they know they will not likely need to use the information in the reading. Because of this, many welders do not know all the meanings of welding symbols.

How Challenging is it to Learn Welding Symbols?

You may be wondering how difficult it would be to learn all the welding symbols and letters. Like any profession, you can learn anything from a book or listening in class, but the best teacher is experience.

While many welders are book smart with symbols and codes, they may not truly become adept until they have been in the profession to practice and hone their skills. Many welders take additional courses after they achieve their welding certificate so they can hone their craft.

In the article, How to Read Welding Blueprints Like a Pro, Pierre Young explains that the art of reading welding blueprints is something that takes time and practice. Although an individual may have taken courses to learn the basics, they may not be fully prepared to read complicated blueprints. The most detailed blueprints are even challenging for experts to read.

What Type of Welding Jobs Require Reading Blueprints?

When you think of blueprints, your mind likely goes to a contractor using blueprints to build a house. While this is true, there are blueprints for many other jobs, welding included.

Some jobs that require a welder to read and understand blueprints are:

- Mechanical welders

- Robotic Welder

- Construction welder

- Bridge fabrication inspector

- Structural metals supervisor

- Manufacturing welders

- Vendors (manufacturing and industrial distributors)

- Welding inspector

This list is not an extensive list of welding jobs that require the knowledge of blueprints, but as you can see, it is quite extensive and bridges several different arenas in the welding field. In the past, reading blueprints was considered an extra skill possessed by some welders; however, it is now becoming more frequently looked at as a necessary skill by employers.

If you are looking at being a sales representative for industrial or manufacturing welding tools and items, it is vital that you can accurately read welding blueprints. This will help you as you guide potential customers toward the best machines and materials for their projects. While it is not a requirement, it would make you a more qualified and respected representative of the company you are working with. It will also help buyers place more trust in you and the company you work for.

Can You Get on The Job Training in Blueprint Reading?

If companies prefer welders that can read blueprints, you may be wondering if they provide on the job training for the skill. According to the article 9 Basic Steps to Read Welding Symbols, many companies can’t make blueprint reading required because it would limit the candidate pool because of the lack of qualified welders.

Some companies may provide a trainer or resources to help welders attain this certification once they are employed. However, many companies don’t have someone they can spare to work on training, so it can be problematic when an individual has the desire to learn how to read blueprints.

Should You Take a Course to Learn to Read Blueprints?

When beginning a career, there is typically a desire to earn money as well as a factor of enjoyment. If your plan as a welder is to advance through the ranks, it would be advantageous to take a course to learn how to read blueprints accurately. Not only will this make you more knowledgeable as you hone your craft, but it will also make you more appealing to employers and will set you apart from many other applicants.

What is the Course Called?

According to the AWS, the course you will need to take is called Endorsement Structural Drawing Reading. This course will take you through the process of reading and understanding welding blueprints. When you choose to take this endorsement, you may need pre-requisites, so it is essential to check into the requirements before signing up.

Cost

One factor that plays a huge role in decisions made when choosing endorsements is the cost of the endorsement. The cost for this endorsement is not cheap, but it will help you long term when you go to procure a job that is better paying than most welding positions. When you sign up, you can expect to pay between $300-$600. The cost varies depending on your membership status with the American Welding Society. If you are a member, the cost will be on the lower end.

Where do I Take the Course?

Many welding courses are offered online or in a seminar, but it does not appear that online work is an option for this endorsement. According to the handbook, this is a completely independent study. Because the amount of content covered is so vast and in-depth, it may be beneficial to seek out a study partner or mentor to help you prepare for the assessment.

Do I Take a Test?

At the end of your coursework, you will be expected to take a test on the material you learned. According to the AWS, you must obtain a score of 72% to receive the endorsement. The assessment is closed book and must be completed in two hours.

Is the Endorsement Forever?

Many endorsements that welders have require a specific time of renewal or recertification. The good news is that this endorsement does not require any form of renewal or recertification. It will be essential to keep up with new mandates and updates through the AWS to ensure this does not change. The last thing you want is to be left without an endorsement that you worked so hard to achieve.

While an endorsement in blueprint reading doesn’t necessarily mean that you will get a high paying welding job right out of the gate, it will not hurt your chances of obtaining a job that may be coveted by many other welders.

How Long Does It Take?

Because this is a self-guided course, you can take as long as you need to prepare for the exam. The critical thing to remember is that you need to work at your own pace, and you need to make sure you are entirely comfortable with the material before you try to take a test on the material.

You can take the test more than one time, but it would be less frustrating if you only had to take it one time. Therefore, it is crucial to take your time and prepare accordingly for the assessment.

Tips and Tricks to Reading Welding Blueprints

If you are looking for insight when it comes to the seemingly overwhelming task of reading blueprints, follow these steps:

- Make sure to know what the welding symbols mean.

- Understand the dimensions and angles required for the job.

- Most important: Take your time to fully read and understand the blueprint before starting the job. Taking the time to do this upfront will save you a lot of time and frustration during the project.

While these three things aren’t necessarily a magic trick to understanding welding blueprints, they will certainly help you to begin the task.

Final Thoughts

If you are a welder that is questioning the importance of taking a blueprint reading course, it will likely benefit your career in the long run and will be a good use of your time and money. Welding symbols and blueprints can be extremely overwhelming and confusing to look at if you are not professionally trained.

Even after going through training, you will likely not know everything, but it will give you a heads up when you enter the workplace and are put in a situation of reading welding blueprints. With practice and the necessary coursework, you will be well on your way to reading and understanding welding blueprints.